Interested in 3D printers but don’t know which one to buy? If you’re looking for a worthy machine, visit Top 3D Shop and check out our 3D printer reviews, we’ll help you choose the machine you need!

Researchers at the Guangzhou Nansha 3D Printing Innovation Institute of China are engaged in the development of a unique 3D printer based on laser stereo lithography technology that can print teeth and dentures. As you know, the principle of operation of a stereolithographic 3D printer is to cure a liquid photosensitive polymer resin under the influence of laser radiation.

Unlike other stereolithographic 3D printers, in which the resin hardens in thin layers, this printer is capable of printing materials with a higher viscosity (5-6 times higher than the viscosity of a conventional stereolithography resin). As a result, researchers were able to master printing with porcelain, and now with this printer you can make full dentures and a metal filler, which is used in the manufacture of fillings and dental crowns. They also experiment with different biomaterials.

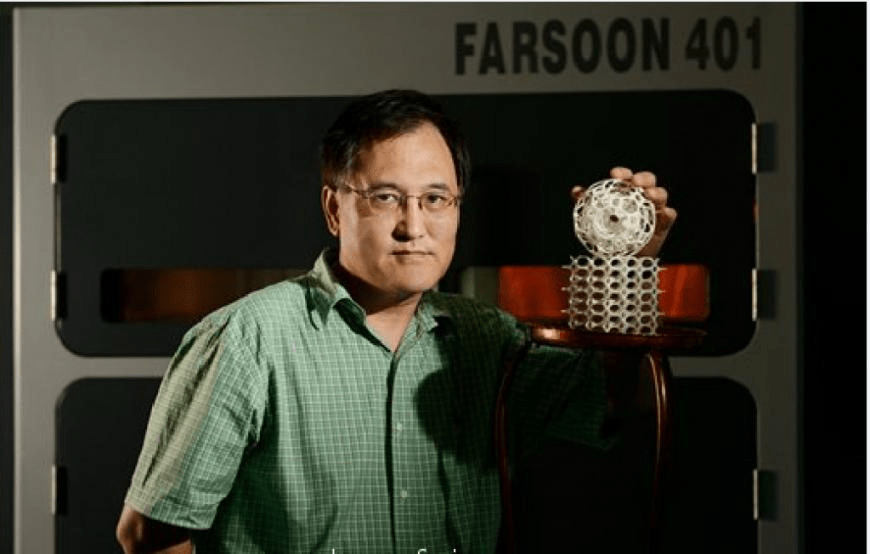

Now the director of the institute, Xu Xiaoshu and his team, are correcting some errors and shortcomings in the operation of the 3D printer, which will soon appear on the market. Although the principle of its work is mostly based on the same technology as other modern 3D stereo printers, he adopted a couple of technical aspects typical of FDM / FFF 3D printers, in particular with regard to the unique extrusion system. Its distinguishing feature is the extrusion of material under high pressure. As a result, the arsenal of materials for this 3D printer is much wider than that of its counterparts.

Due to the viscosity of the material used during printing, no support is required (well, only in the rarest cases), which means that the finished product is neat, undeformed and does not require post-processing.

In terms of speed, a conventional 3D stereolithographic printer takes about 10 seconds to print a single layer, and the development of Chinese experts takes only one second. The overall print speed is twice the speed of other 3D printers. Also, the novelty boasts rather large parameters of the printing platform - 400 mm x 800 mm.

Xu is confident that ultimately this 3D printer will revolutionize the manufacture of porcelain teeth. Today, in most cases, dentures are made by specialists manually. Naturally, they take a lot of time to cut and grind. A Chinese 3D printer performs all these steps automatically, which means that the risk of errors and the total cost of work are significantly reduced.