Interested in 3D printers but don’t know which one to buy? If you’re looking for a worthy machine, visit Top 3D Shop and check out our 3D printer reviews, we’ll help you choose the machine you need!

Dr. James Otton of the Victor Chang Cardiology Research Institute in Sydney, Australia, said that he periodically has to implant a unique Watchman cardiology device (Watchman), developed by Boston Scientific and approved by the US Food and Drug Administration March of this year. Implantation is performed according to fluoroscopy and transesophageal echocardiography. A three-dimensional image of the heart is created by the results of multilayer computed tomography.

“The fact is that the left atrium ear is a very complex device, and even if you have all the necessary data, it may still not be clear where to implant the device. In addition, it can be difficult to determine the size, ”explains Dr. Otton.

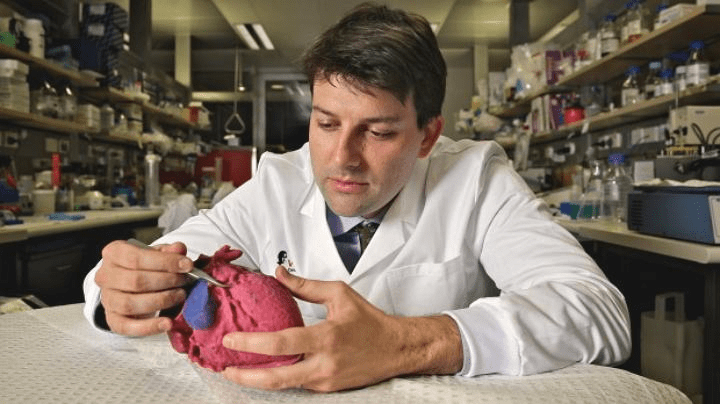

To plan the operation in advance, doctors began to resort to 3D printing technology and produce realistic models of patients' hearts. Now they can study “the complex anatomy of the left atrium and determine the size and location of the Watchman, which was previously difficult to achieve even with the most advanced methods.”

The last time doctors performed an operation using 3D modeling and printing technologies was given to a 74-year-old man with paroxysmal atrial fibrillation.

Using the data obtained as a result of CT scanning, a team of researchers printed a 3D model of rubber-like material that simulates the atrial mechanical properties of the left atrium. Then she installed three Watchman devices in the model, determining their location according to the results of another CT scan. When all the devices took their place in the 3D model, the team was able to analyze the anatomical deformation and find the optimal solution.

Initially, the team planned to install a smaller device. However, having studied the CT scan data with a good example, she decided to implant another version of the device.

According to Dr. Otton, it took about 30 minutes to make a patient’s left atrium model. As for the cost of materials, they cost researchers only $ 100-200.

“I don’t want to exaggerate the merits of 3D printing in this particular case, because in fact this is just one way to test the theory in practice,” says Dr. Otton. - It seems to me that 3D printing has great potential, including in medicine. It will also be useful in education and planning, but this is still a long way off. I think we have to wait a year or two. ”