Are you thinking of getting a 3D printer for your home or business? Visit Top 3D Shop and read our latest reviews. We will help you get the machine you need!

CAE Healthcare has developed the first Fidelis (Fidelis Maternal Fetal Simulator, MFS) simulation robot, using 3D-printed parts created by Stratasys. It will help educate obstetricians on how to deal with complications during childbirth.

Although modern technology and medicine have largely secured the birth process, complications and problems sometimes occur. Strong physical, psychological and emotional stress on the woman in childbirth can lead to a number of problems, which means that doctors and obstetricians must clearly understand how to act in such situations. The MFS robotic system developed by CAE with the support of Stratasys can now significantly help in training specialists.

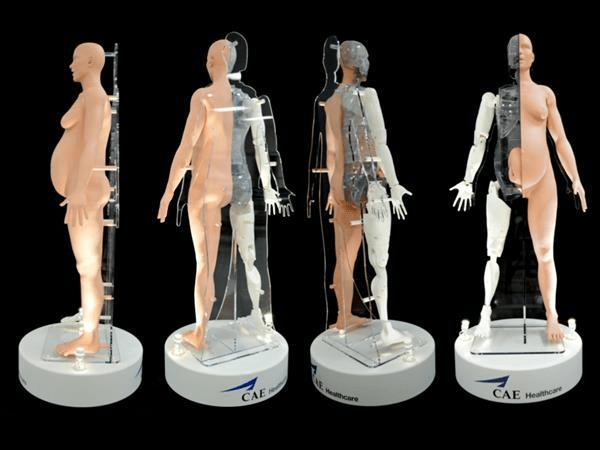

Partially printed on a 3D printer, the robot can simulate the breath, the heartbeat of the woman in labor, and the birth process itself. The device consists of hundreds of components and is equipped with an electronic control system that displays the necessary physiological data of the mother and fetus and even simulates the crying of a child.

“Creating a humanoid simulator is a very complex and painstaking process. In particular, special attention must be paid to the interaction of various parts responsible for physical processes. The creation of such a robot was significantly complicated by the addition of moving and shape-changing elements. We needed to create many small parts in a short time, ”says Giuseppe Mallaci, senior technical designer for the MFS robot.

CAE turned to Stratasys for help in creating components for the simulator using various 3D technologies, including stereo lithography (SL), fused deposition modeling (FDM), laser sintering (LS) and others.

The fetal model can be viewed through a transparent wall made of Accura 60 material. Various techniques and methods were used to create different elements of the simulator. For example, arms and legs were made using LS-technology, for other parts they partially used ID-Light - exclusive Stratasys technology. This made it possible to obtain large light components. Using this technology, you can reduce the weight of the part by 12 times.

The MFS maternity robot simulator can simulate various clinical scenarios of the birth process: normal delivery, instrumental vaginal, fetal tachycardia due to maternal fever, delivery during pelvic presentation of the fetus, depression of the central nervous system of the fetus due to drugs administered to the mother, brachial dystocia, postpartum hemorrhage due to uterine atony, maternal cardiopulmonary failure, eclampsia and umbilical prolapse.

This simulator is a good example of the important role of 3D printing in creating useful devices. The robot is already used in hospitals, universities and training centers in the United States and Canada.