Are you thinking of getting a 3D printer for your home or business? Visit Top 3D Shop and read our latest reviews. We will help you get the machine you need!

The additive manufacturing industry continues to discover new facets of development. However, the question of how to make the process more efficient and materials more wear-resistant remains relevant.

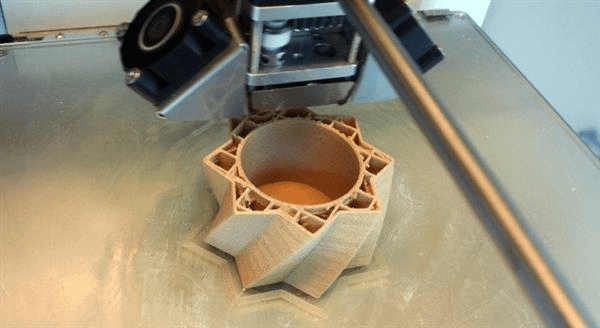

The Swedish company Innventia has created an interdisciplinary consortium called “Would wood” to develop the materials of the future. Its goal is to develop integrated materials and production concepts for the large-scale additive manufacturing of modern wood-based material.

The project includes the development of innovative material for 3D printing, as well as techniques for its production, which will help create furniture and other elements, and in the long term, large-scale projects for smart cities.

Innventia is engaged in the production of research on wood processing methods, as well as the development of complete solutions for the pulp, paper and packaging industries. The company is divided into three areas: biological processing, material processing and packaging.

The main idea is that any new material should be developed taking into account new processing and production methods, such as, for example, 3D printing, in order to be able to optimize its use and, if possible, make it environmentally friendly. In addition, local materials are mainly taken into account in order to reduce transportation costs, intermediaries, etc.

To date, the company has focused on new materials and products created from cellulose and similar substances, as well as on by-products of the food and forest industries. For example, Innventia was engaged in bioplastics created from a reduced polymer. The company also showed that it is possible to create carbon fiber from lignin, a by-product of a kraft pulp mill.

The goal of the project would wood was to modernize existing production techniques for wood products and adapt them to 3D printing. Thus, the project covers the development of materials, robotics, additive manufacturing, as well as the development of tools and methods for creating wood-based mixtures for use in medium and large 3D printers. There is also the collaboration with other projects related to the additive manufacturing process.

“We want to radically change the approach to creating the majority of elements: from furniture and accessories to entire buildings and their components. “We are creating the basis for working with a new type of product - printed on a 3D printer made of wood,” says Mikael Lindström, Innventia's project manager. - We believe that this technology will change our attitude to the concept of rationality in such aspects as living standards, environment, logistics, material consumption, energy and transportation. We live in an exciting time of technological development and understand that wood can serve as innovative, durable and obvious material for the bioeconomics of the future. ”

The multidisciplinary consortium is the idea of three young researchers: Cecilia Silvasti, Kayrokh Moattar, and Lily Huang. Mikael Lindström was appointed an official coordinator. This project is one of 31 projects funded by the Swedish company Vinnov, which helps the development of research. The total investment is about $ 1.8 million.

Wood-based fibers have already appeared on the 3D printing market (for example, LAYWOO-D3, created by Kai Parthy. However, support for such initiatives, especially with existing climate problems, decreasing natural resources and rising oil prices, is necessary as well as the development of the widespread use of wood in the field of 3D printing for the creation of packaging materials, furniture, and even houses and other large structures. Significant progress and results can be achieved if you work simultaneously at the border of industries and directions, design, architecture, robotics, mechatronics, forestry, building materials, as the Innventia Would wood project team does.