Interested in 3D printers but don’t know which one to buy? If you’re looking for a worthy machine, visit Top 3D Shop and check out our 3D printer reviews, we’ll help you choose the machine you need!

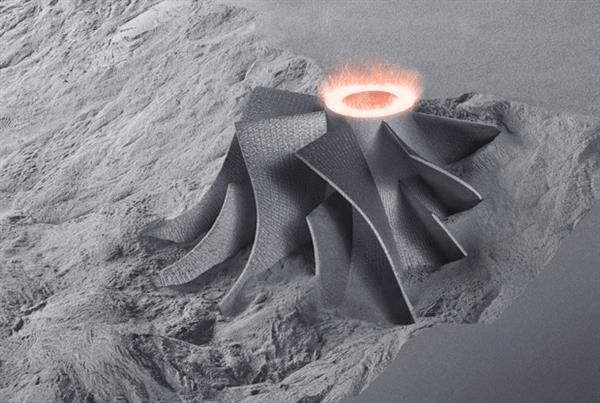

Metal 3D printing has reached unprecedented heights. The smallest details, intricate shapes, high speed - everything with her. And yet it also has its drawbacks, for example, small surface porosity, accompanied by tiny defects and cracks. Scientists have long wondered what is causing this porosity and how to optimize the 3D printing process to avoid it. It looks like the answer has been found.

A team of researchers from Livermore National Laboratory. E. Lawrence (Lawrence Livermore National Laboratory or LLNL) under the leadership of Aibo Matthews and made a unique discovery, the results of which were published in the journal Acta Materialia Online.

The study says the problem lies in the phenomenon of denudation ("exposure") under the influence of a laser fusing metal powder for 3D printing. When the laser moves over the platform covered with powder, a driving force is generated that scatters the powder grains. As a result, where there was a little less powder, tiny gaps and defects are formed.

According to Matthews, his team was the first to become interested in the metal vapor issue during printing. “During this process, the temperature is almost close to the boiling point of the metal, and vapor begins to escape,” he explains. "Until now, no one has thought about what impact they can have on the results of the work."

To study this phenomenon, occurring at the microscopic level, researchers from LLNL commissioned a platform for research on the technology of metal powder melting by laser action at the Fraunhofer Institute for Chemical Technology in Aachen, Germany. Using a microscope of their own design, a vacuum chamber and an ultra-high-speed chamber, they were able to see in detail the process of scattering metal powder when a laser passes through it. Then, armed with the principles of hydro-aerodynamics and computer simulation technology, they recreated a model of the movement of powder particles.

Although the researchers have not yet proposed a solution to this problem, they have helped to understand exactly how the powder fusion process proceeds, which means that they have already taken the first step towards improving the technology. Now Matthews and his team continue to monitor how the surface of products becomes porous in real time and are looking for ways to fix this problem. To do this, they use an advanced diagnostic system and try in every possible way to influence the printing process in order to improve its quality. “Now that we have a better understanding of the physics of the process, we can more accurately simulate it and achieve better results,” says Matthews. Clearly, thanks to the efforts of this tight-knit team, in the future, metal 3D printing can be more accurate and accurate than ever before.