Interested in 3D printers but don’t know which one to buy? If you’re looking for a worthy machine, visit Top 3D Shop and check out our 3D printer reviews, we’ll help you choose the machine you need!

While 3D printers are great tools for prototyping, they have one major drawback: speed, or rather lack of it. Making a 3D model can take hours and hours of time (even at the lowest settings), and you really want to get a glimpse of what you get. Cornell University students Huayshu Peng and Rundong Wu proposed an original solution to this problem. They developed the On-The-Fly Print platform, with which you can get a sketch of a future prototype in minutes. Moreover, in the process of printing, the user can return to modeling and make any changes that he considers necessary. This system can rightfully be called a tool for step-by-step high-speed prototyping.

Students presented their groundbreaking project at the Conference for Human-Computer Interaction, held in San Jose, California, May 7-12. They also prepared a report "On-The-Fly Print: Step-by-Step Printing in the Simulation Process" University professors Steve Marschner and Francos Guimbretiere acted as leaders of the project, which received support from the US National Science Foundation.

According to the students, they wanted to break down the barriers that limit digital 3D modeling. “Since the user cannot see his product in advance, in many cases the result is not very successful, and then everything has to start over,” explains Huayshu Peng. "In my opinion, the most logical decision was to come up with a system that can make skeletons of future products, so that the user has a physical version of what he got in the 3D modeling program before his eyes."

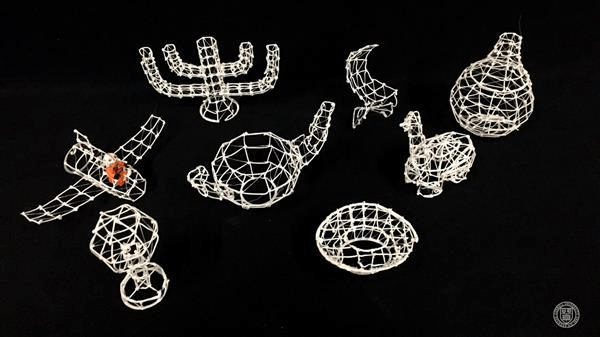

It all started back in 2014, when Professor Guimbretiere assisted student Stephanie Müller on the WirePrint program. It took place at the Hasso Plattner Institute in Berlin. With this program, you can get an approximate wireframe mesh of the model and then print it on any 3D printer. Since this is just a "wire" frame, the speed of its production is dozens of times faster than the speed of the model itself. Working on the On-the-Fly Print project, students refined the initial idea and prepared a powerful platform for it that automatically starts the 3D printing process even during the modeling phase.

It sounds too unrealistic, but On-the-Fly Print really allows you to print in parallel with the work in the CAD program. “You add elements to a digital model, and our 3D printer grows its wire frame at the same time. During the work, the designer can pull the working platform (fixed with magnets) out of the printer and carefully examine the resulting frame. Then the platform can be installed in place and the necessary edits can be added to the digital model, while the printer adds the same changes to its physical version, ”the developers explain.

The project was implemented on a Mini Kossel delta 3D printer developed by the students themselves. It is powered by a Beagle Bone Black computer connected to a CRAMPS 2.0 module. The developers have been able to significantly speed up the printing process by passing thicker filaments (1 mm thick) through an elongated printhead that can reach the farthest points of the wireframe. “In our case, speed is more important than quality,” the authors of the project explain. Thick ABS filaments harden in seconds thanks to two water spray guns. The result is a unique 3D printing platform that can create 28 x 28 x 28mm wireframes in about 32 seconds (two minutes faster than WirePrint).

But the main advantage of this machine is that it can correct the model at any point, not just from above. For this, the delta 3D printer is equipped with a circular acrylic rail with a radius of 260 mm, which gives six degrees of freedom: five in motion and one for the extrusion system. As a result, the print head can reach almost anywhere on the model. This can be clearly seen in the video below, where the prototype of the aircraft is being created. Thanks to the retractable blade, the system can even correct mistakes and remove pieces of the frame to prepare the site for further work.

Such sophisticated technical equipment requires very smart software. As the designers themselves explain, this program must follow all the stages of modeling. She got a special plug-in for Rhino that instantly transforms G-code geometric shapes for 3D printing. “In additive operations, it creates a wireframe mesh, as well as all the necessary connecting structures, in subtractive operations, it removes pieces of the frame and makes the necessary edits to the structure,” the developers say.

Moreover, this plugin even knows how to monitor print queues, thereby optimizing the work process and not distracting the designer. As if a new geometric shape or a change already exists