Interested in 3D printers but don’t know which one to buy? If you’re looking for a worthy machine, visit Top 3D Shop and check out our 3D printer reviews, we’ll help you choose the machine you need!

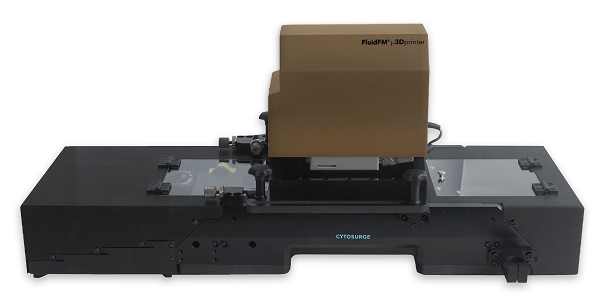

The Swiss company Cytosurge has developed the FluidFM 3D printer for micro-printing metal products. Ultra-high resolution devices are measured in fractions of a micron.

The device combines microfluidic systems with the principle of electrolytic metal deposition. The metal ions are delivered as a solution by means of a micropipette (pictured below) with a nozzle diameter about 500 times the thickness of a human hair, and the delivery rate is determined by a special system capable of regulating the flow on a femtoliter scale.

The Fluid FM 3D printer is used to build volumetric metal shapes at micron and even submicron scale. Potentially, the technology can find application in the production of customized electronics, sensors and micro robots. The construction area of a 3D printer is also extremely small due to the specifics of the technology, not exceeding 200x200x200 micrometers.

The size of the working chamber, on the other hand, reaches 100x70x60 mm with the expectation of printing microstructures on top of articles or substrates of complex shapes fixed in the chamber. The positioning accuracy of the deflected pipette when moving the "head" to a new workstation reaches 250 nanometers. The deflection of the pipette during printing is carried out due to deformation under the influence of laser radiation.

So far, the device is only used for copper printing, but the company is working to expand the range of consumables to titanium, nickel and tin, and is also exploring the possibility of using alloys and polymers.